Gun safe corrosion is a real threat

Why are there are so many products on the market designed to slow or stop corrosion in a gun safe?

Most armorers will tell you if a gun is properly cleaned and oiled it should not rust.

Yet in gun safes, corrosion is a hot topic and they sell millions of dollars in products to stop it.

Excerpt from SHOT Show presentation.

Gun safes and rust

https://www.youtube.com/watch?v=eRPz6IKdiK4

why do guns rust so fast in gun safes?

Modern gun safes are built with a thin steel shell, lined with gypsum board (drywall) and then carpeted. To understand the corrosion issues you have to look at the chemicals contained in these materials and how they react.

Formaldehyde: CH2O

Formaldehyde is used in drywall manufacturing. It is a dispersing agent used in drywall slurry. These dispersing agents are called sulfonated naphthalene-formaldehyde condensates. As the term implies, these formulations involve a combination of formaldehyde and naphthalene. The agents vaporize in your safe, creating a potentially caustic environment for metal and wood. Museums ban the use of formaldehyde in areas where artifacts are stored. Formaldehyde is also in the adhesive used to attach the carpet interior in most safes.

Sandvik laboratory test results for CH2O (formaldehyde) and carbon steel: corrosion rate over 1.0 mm/year. ~ Serious corrosion. The material is not usable.

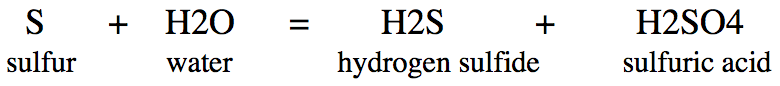

Elemental Sulfur: S

Sulfur is found in drywall particularly from China. Sulfur reacts with trace amounts of water (humidity) to form hydrogen sulfide and sulfuric acid.

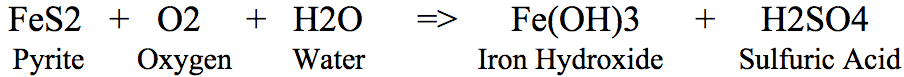

Pyrite:

Pyrite (iron sulfide) also known as “fool’s gold” is a very common mineral. It is present in the gypsum mined to make drywall. There are small amounts in gypsum in the U.S. and much larger amounts in gypsum mined in China. The pyrite ends up in the drywall. While this is not a big deal when it comes to home construction, you do not want it in your gun safe. Pyrite (Iron sulfide) reacts with oxygen and water to form iron and sulfur in the forms of iron oxide-hydroxide (rust) and sulfuric acids.

Sulfuric acid is particularly aggressive when it comes to corroding metal.

Ferrooxidans – Bacteria

This is a type of bacteria that eats metal. It lives on the pyrite in the drywall. It is this bacterium that breaks down pyrite into iron hydroxide and sulfur-based acids. However, it doesn’t stop there. Ferrooxidans will consume many other metals. Ferrooxidan bacterium is used in mining operations to strip metals in low-grade ore.

Does your gun safe ever smell like sulfur?

Next time you open a safe, see if you detect a slight earthy or sulfur smell. It’s there and gets stronger the longer the door has been closed. I have noticed it, particularly in cheap safes on the sales floor in some big-box sport discount stores. That smell is the above processes in action and it will cause gun rust very quickly.

As you can see, there is very good reason for all the corrosion control products in the safe industry. Modern gypsum (drywall) based gun safes are corrosive.

Why use drywall? It is cheap, easy to use and heavy. The weight is important. The gun safe industry wants their safes to be heavy. People think that heavy safes are “safer”. However, it’s smoke and mirrors designed to hide the fact that the industry has moved away from traditional safe designs. Modern gun safes are built to the UL Class RSC standard and are not, according to UL, a true safe.

So how did we get here?

How did the gun safe industry end up producing a product that can destroy the very item it is designed to protect?

It started in the late 1970s. Up until then, gun safes were based on the original design of Silas Herring. He used a sandwich design of thick outer steel, thin inner steel, and plaster or cement in the middle. This has been the standard fireproof safe design for over 100 years. In the 1980s the gun safe market started growing and as demand for safes grew, a bunch of new companies entered the market. To reduce costs and speed production, these new producers dropped the original Silas Herring design in favor of cheaper, lighter materials.

They eliminated the thick outer steel. They eliminated the plaster or cement filler. The thin inner steel cabinet became the outside steel box. They lined this thin walled box with drywall then carpeted over it. This is the modern gun safe.

When these changes occurred UL (Underwriters Laboratories) created a new classification. Class RSC–Residential Security Container. The RSC is the standard gun safe sold in most stores throughout America.

If you have purchased a gun safe made after 1980 it is most likely a UL Class RSC. It is drywall based and subject to all the corrosion issues above. Your best defense against corrosion is still well-cleaned and well-lubricated firearms. It is important to open the door regularly and let your safe air out. This will reduce the corrosive sulfur compound buildup. Dehumidifiers slow the process by lowering humidity, but they don’t stop it.

Removal of corrosive materials.

The interior of a gun safe can be removed and replaced with safer materials. Products like SBI Micore-300 can be used to replace the drywall. However, this is an extensive modification and will take some time and skill to properly fit and install the new fire board.

How do you avoid all this? Do not buy a gun safe with drywall or carpeting. That eliminates just about every safe sold in America. Otherwise, Ft. Knox, Browning, American Security, and a few boutique producers offer safe models with the Herring double walled steel design. These models do offer some security and modest fire protection, and the inner steel will provide good corrosion protection. These safes start at around $10,000and go up to 20K+.

This brings up the following questions. Why buy a gun safe?

Why buy a gun safe?

The data suggests that common UL Class RSC safes offer little in the way of security or fire protection.

So what do you do? How do you protect your investment?

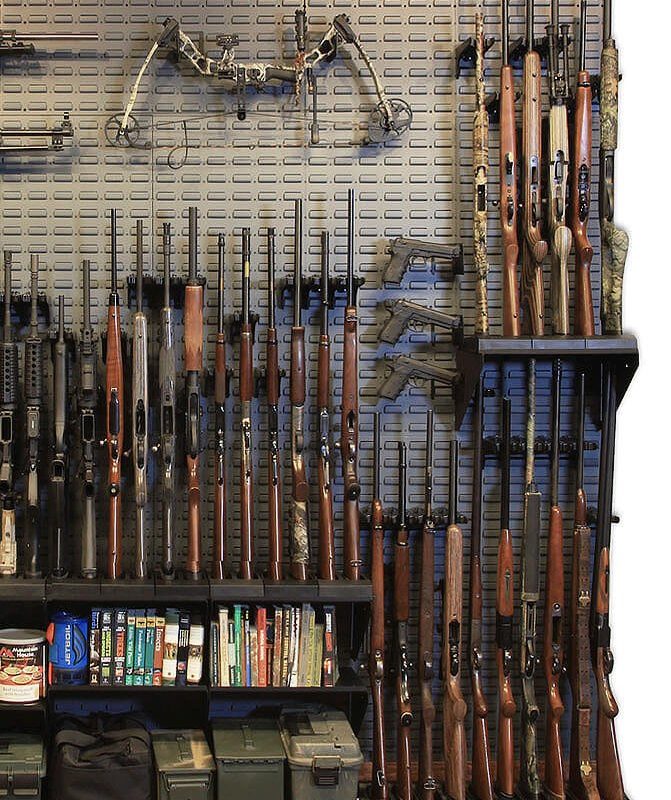

Shy of spending north of , consider steel cabinets. They are just as secure, and most likely offer the same fire protection of a big heavy drywall based UL – RSC gun safe.

There are other advantages of eliminating the drywall from gun cabinets. Weight, going lighter is better. It is easier and certainly gives you more flexibility in how and where you store and secure your firearms.

Consider SecureIt Tactical Model 52. This gun cabinet that will provide a strong theft deterrent, is lightweight and easily concealable. Perhaps best of all, it won’t corrode and destroy the very things its meant to protect.

The all steel design of our gun cabinets is far safer for your firearms in terms of corrosion. Smaller steel gun cabinets can be located throughout a home, allowing you fast access to locked firearms in a crisis situation.

Smaller lighter modular cabinets can be secured anywhere in a home, condo, cabin or RV. Modular cabinets can bolt together and expand to meet growing needs.

Firearms storage is going to change. The gun safe industry produces and markets a product based on the illusion of security. Their stated gun capacity is outright deception. They are not fireproof and the materials used inside a safe promote gun corrosion. You can fool some of the people some of the time. Eventually, it all catches up. That is what is happening now.

SecureIt is the leading supplier of weapon storage systems to the US Government. We have revolutionized military armory function. We want to do the same for home firearms storage. SecureIt has taken the leadership position in modern firearms storage, and things will change quickly over the next few years.

Learn More about modern gun storage

Shop SecureIt Gun Safes