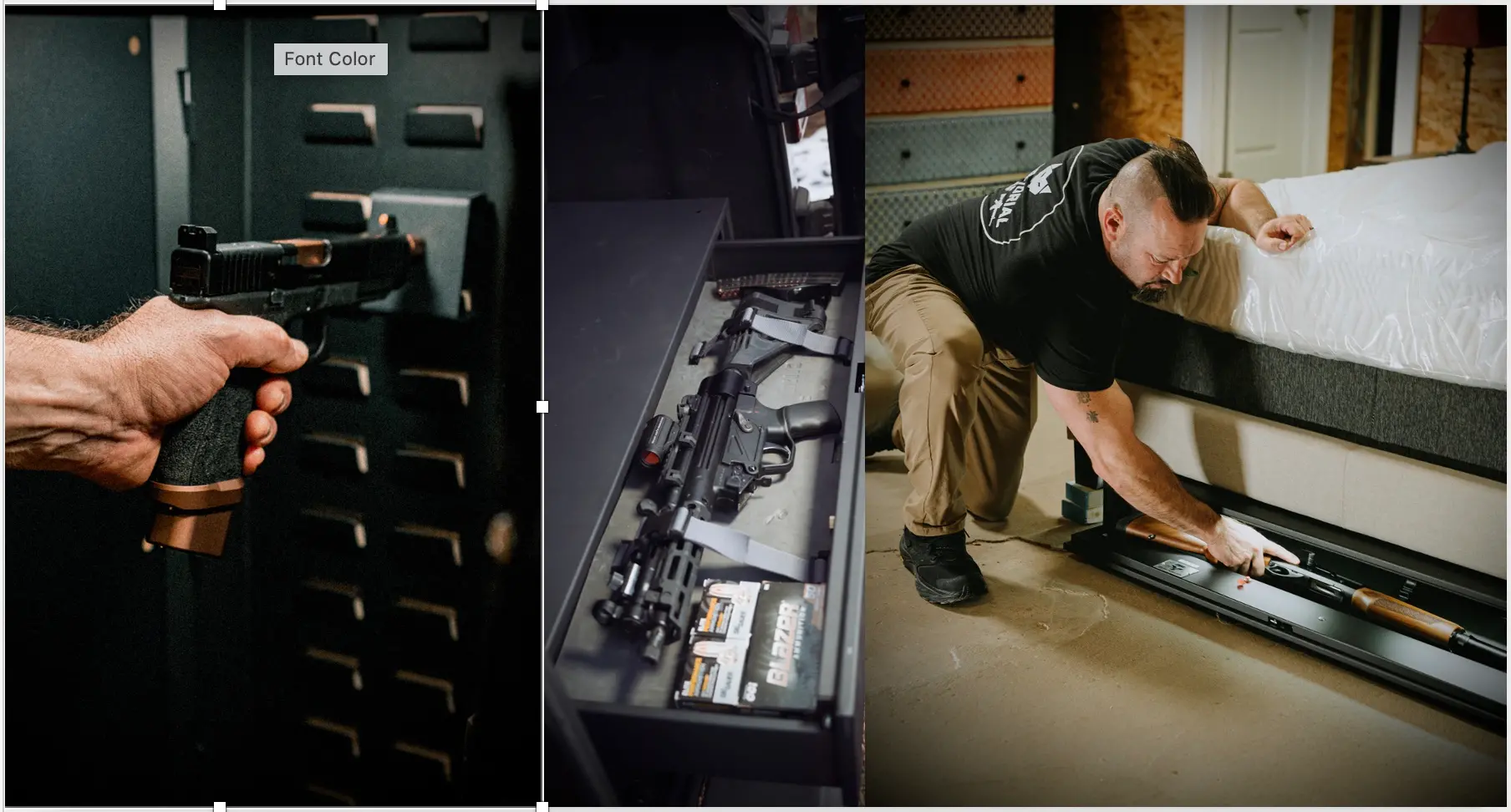

Pistol, AR-15, Shotgun – The best for home defense is?

Considering a pistol, AR – 15, or a shotgun for your primary home defense weapon? Great choices! And each can be effective depending on the type of home you have, how much space you have, the room you need protection in, and what is or is not allowed by law. As states